Differentiating between yeast products and their derivatives

Before we can discuss the different yeast products, their vast versatility of use, and all they have to offer biochemically, we first need to investigate this tiny cell itself.

No more than four to five micrometres in size, yeasts are part of the fungi family and are single-celled facultative anaerobes. This means that, although they prefer oxygen, it is not a prerequisite for their growth and survival. Approximately 500 species of yeast have been identified. Most yeast species are no more than insignificant saprophytes, living on dead or decaying material, adding no value nor posing any threat to animals and humans. Some species have been shown to act pathogenically, but more interestingly, some species and their derivatives are particularly useful in biotechnology.

When yeasts find themselves in the presence of oxygen (aerobic conditions), they convert oxygen and sugar into carbon dioxide and usable free energy for cell growth. When oxygen is deprived, fermentation is less efficient and the yeast grows much slower, producing more metabolic by-products such as ethyl alcohol. Simple sugars are then fermented into ethanol and carbon dioxide, making them more suited for brewing or spirit distilling. The most common commercially used yeasts include:

- Saccharomyces cerevisiae, also called baker’s yeast, which is commonly used by breweries, wineries, and spirit distilleries.

- Kluyveromyces marxianus, also called whey yeast, which is often found in the paper industry where it utilises the pentose sugars from processed wood pulp to form paper.

- Candida utilis, also called torula yeast, which is commonly found in the food industry where it can utilise lactose as a substrate.

Biochemical use

From hieroglyphics depicting fermentation that date as far back as 5 000 years into human history, yeast-based products and their use in fungal fermentation have been around since at least ancient Egypt. Yeast has long been used to produce bread and ferment alcoholic drinks such as wine or beer, with Europe only later utilising it to produce spirits in the 18th century.

Over the past century, yeast has not only grown in popularity in the production of human food but has also seen many advances in livestock feed production due to its exceptional fermentative and nutritional properties. Coming back to versatility, yeasts may be single-celled, but they are far from simple. Especially at a time when nutritionists are looking for natural alternatives and trying to reduce their dependence on antibiotic growth promoters, yeast and yeast-derived products are becoming more popular. Yeasts have been shown to exert positive effects on animal health and wellbeing by stabilising the intestinal flora and reinforcing immune modulation.

Yeast itself is a good source of crude protein and amino acids, but the various components of the yeast cell and the various ways in which yeast cells are processed give this small organism its versatility.

Table 1 Different kinds of yeast products.

| Active dry yeast | This can be defined as the dried, centrifuged yeast cells after bioreactors or fermenters are inoculated and fed with nutrients and oxygen and allowed to ferment. Active dry yeast is a live yeast, with 95% dry matter, and is often used in animal feed as a probiotic. |

| Whole-yeast inactivated cells | These can be defined as an active dry yeast after it has been heat-inactivated, which prolongs the shelf life. This product is most often derived as a by-product due to secondary fermentation from the brewing industry. It is used as a flavour enhancer but is also a source of B vitamins and protein. |

| Yeast culture | This can be defined as a mixture of all the metabolites that are left over after fermentation, typically including both dead and live yeast cells, cell fragments, cell contents, and all products produced in the process, such as simple sugars, carbon dioxide, alcohols, amino acids, and organic acids. There is often a lot of variability in product quality or composition. |

| Nutrient-enriched yeasts | These occur when yeasts naturally incorporate nutrients into their cell walls or are artificially fortified with nutrients, thus making such nutrients more bioavailable, which may increase the value of the yeast product fed to animals. Examples include yeasts that naturally produce vitamin D when exposed to ultraviolet B rays, or when certain yeast strains incorporate inorganic trace minerals into their cells, such as selenium, converting it to organic selenium. |

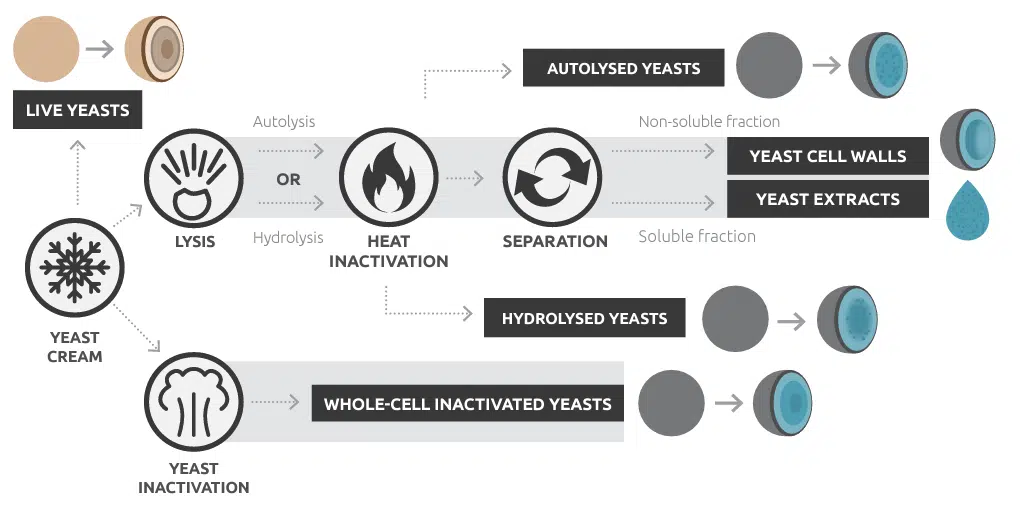

| Lysed cells | These can be defined as yeast cells that have been enzymatically digested to break down complex structures into more simple ones. There are two ways to lyse yeast cells: Autolysis, where endogenous enzymes are allowed to cause self-digestion. This process is not very controlled and so the final product quality is rarely guaranteed. The nutrients from this process tend to be less digestible. Hydrolysis, where the endogenous enzymatic action is supplemented by exogenous enzymes. This process gives more control and offers more digestible nutrients. There is no separation step after digestion and hydrolysed yeast cells may still contain cell wall components and yeast extract. |

| Yeast extract (YE) | This can be defined as the water-soluble fraction of the lysed yeast cells after separation from the cytoplasmic content has occurred. These tend to be rich in crude protein, peptides, free amino acids, and nucleotides. The type of yeast extract depends on the enzymes used during the lysis process. |

| Yeast cell wall (YCW) | This can be defined as the insoluble fraction of the lysed yeast cells after separation from cytoplasmic content has occurred. This product consists of between 30% and 40% dry-weight cell walls that consist of two layers: The external layer contains carbohydrate structures such as mannan-oligosaccharides and D-mannose, which may bind to the flagella of pathogens or act prebiotically, feeding the beneficial gut microflora. The internal layer contains carbohydrate structures such as β-glucans, which have been shown to modulate or prime the immune system and may even bind some mycotoxins. |

Due to the beneficial effects described above, YCW specifically has become a popular choice for nutritionists because cell wall components may hold many benefits in the face of current challenges. However, these cell wall components may not always be available to the animal because animals do not produce sufficient enzymes in their gastrointestinal tract to release the carbohydrates from the YCW. The good news is that some technologies exist where these functional carbohydrates have already been enzymatically hydrolysed and broken into pieces, thus making them more bioavailable to enhance their effect on animal performance.

Conclusion

Not all yeast products are created equal. Yeast itself not only holds benefits for animal feeding but, more specifically, what yeasts are made of should give this tiny, once-thought-simple organism a legitimate space in your formulation endeavours.

To read the original publication, click here to download the PDF.

Very informative and detailed one for yest and it’s uses .