As poultry production begins to sore, we must act before the excreta hits the fan!

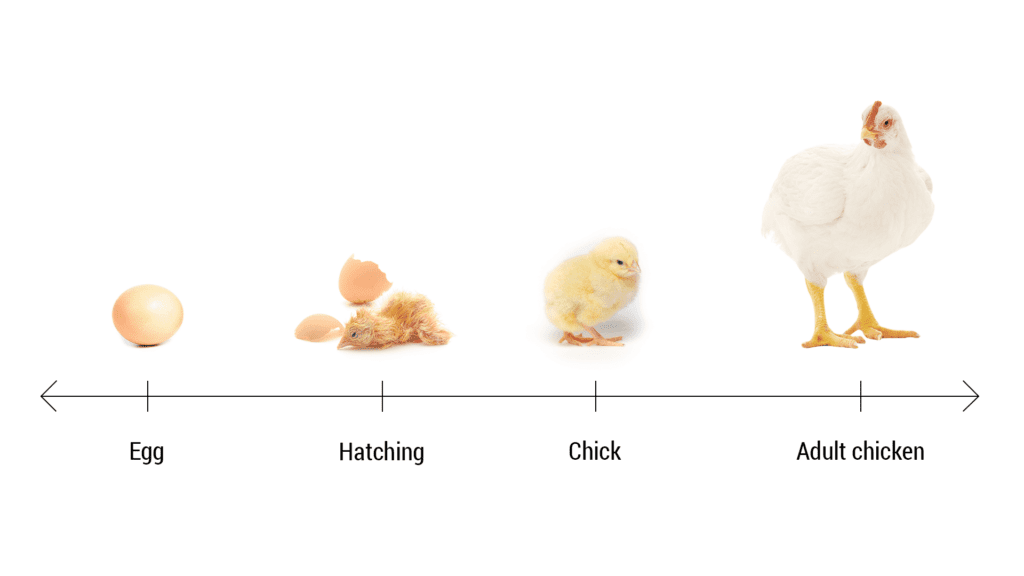

It is without question that the poultry industry is indispensable when it comes to providing the world with an affordable source of quality protein. According to Poultry Trends, global poultry meat production reached approximately 125 million metric tons in 2018. To bring that figure closer to home, a total of 983 million broilers were produced for slaughter in 2018 (Key market signals in the broiler industry, by SAPA). Considerable research and millions of rands have been spent by nutrition and genetics companies alike to ensure that the broiler of today is as efficient as possible. However, there is a big, smelly elephant in the room that has yet to be addressed and over the past couple of years, the stench has become so unbearable that environmental activists and poultry producers alike are beginning to raise concerns. I am, of course, talking about the large amounts of excreta and litter that gets produced by the poultry industry.

The challenge

The responsible disposal of poultry waste has always been an afterthought for poultry produces, with traditional methods including its application as fertiliser for crops; however, the amount of waste being produced is starting to increase as a direct consequence of the increase in production. Due to increasing environmental concerns, the poor handling of poultry waste has come under scrutiny. These concerns are not unfounded, and to understand them we must take a look at the composition of poultry waste and, more specifically, the mineral phosphorus (P). Phosphorus is naturally found in plant-based poultry feed ingredients, with 70 – 80% of the total P content being found in the form of phytate. This form of P is poorly digested by the bird, rendering the P unavailable and resulting in almost 45% of the P consumed by the bird being excreted. The traditional method of applying poultry waste to fields can be compared to a sponge soaking up water. At first, the sponge can absorb and retain the water, but as more water is applied, the sponge begins to reach its threshold, and instead of absorbing water begins to leak water. The same principle can be applied to the application of poultry waste to fields. If not managed properly, the amount of excreta being applied to the field can outweigh the field’s capacity to absorb the nutrients. This can result in the accumulation of surface runoff that is high in water-soluble P. This surface water finds its way into water bodies such as lakes and rivers and, if left unchecked, this can lead to over-enrichment of P in those water bodies, resulting in a process known as eutrophication. Eutrophication has been linked to harmful algae blooms, which in severe cases can result in the loss of flora and fauna biodiversity, as well as rendering those water bodies unfit for human consumption. So, the question we should be asking ourselves is, how can we ensure the sustainability of the poultry production industry without compromising on food security?

The scientific solution to sustainable poultry production

On the surface, it may seem like an impossible task to satisfy both parties without adversely affecting the other, and such negotiations and planning often lead to impasses. For example, some parties might say we need to reduce the number of birds being produced; however, that would not be wise, as that would not only negatively affect food security but also job security. However, all is not lost as there exists a feed additive product on the market that can act as a catalyst for sustainable poultry production without compromising on food security. The product I am referring to is non-other than the enzyme phytase. When supplemented into poultry diets, phytase helps to catalyse the release of phosphate groups from phytic acid, making the once unavailable P found in plant-based feed ingredients readily available to the bird. Now more than ever there appears to be a plethora of enzymes on the market, all claiming do the same thing. However, there is one product that stands head and shoulders above the rest. The implications of supplementing such an enzyme goes above and beyond simply reducing the amount of P found in the excreta. This product has been scientifically shown time and again to improve production performance as well as reduce the overall cost of poultry diets (Dersjant-Li et al., 2020). The enzyme I am talking about is of course Axtra® PHY, and it is just one example of how science can be used to accommodate both sustainability and production, without upsetting either party. The importance of making use of a scientifically proven product to optimise sustainable poultry production is imperative now more than ever before. So, before the elephant in the room becomes too noxious to bare, ask yourself the following question. Are the products you supplement eliciting a positive response in your flock?

For more information

Axtra® PHY is just one example of how Chemuniqué is using scientifically proven products to sustainably produce feed for food for the future. For more information on our portfolio of scientifically proven products, feel free to visit the Chemuniqué website to find out more.

Intern: Poultry

Well done, Gareth! Most interesting.