In commercial broiler operations, feed accounts for majority of the input costs, and dietary energy represents up to three quarters of the cost. In poultry, there are major economic implications to an over- or undersupply of dietary energy, as this leads to either reduced or excess feed intake, imbalances in the protein-to-energy ratio, poor feed conversion ratios, poor production performance, and feed wastage. The assumption that maize has a consistent nutritional value is changing as more studies are conducted and variability is shown between batches. The large variation in the energy of maize has significant implications for the feed industry since it implies a potentially large variation in energy available from maize included in feed formulation and suggests that the use of generic matrix values for maize energy estimation are inaccurate.

It has been shown that physical characteristics such as kernel vitreousness and hardness may explain some of the variation in the observed energy of maize. However, current prediction equations used by the South African feed industry for maize energy estimation do not consider differences in kernel hardness vitreousness.

Understanding the maize kernel

Proximate composition

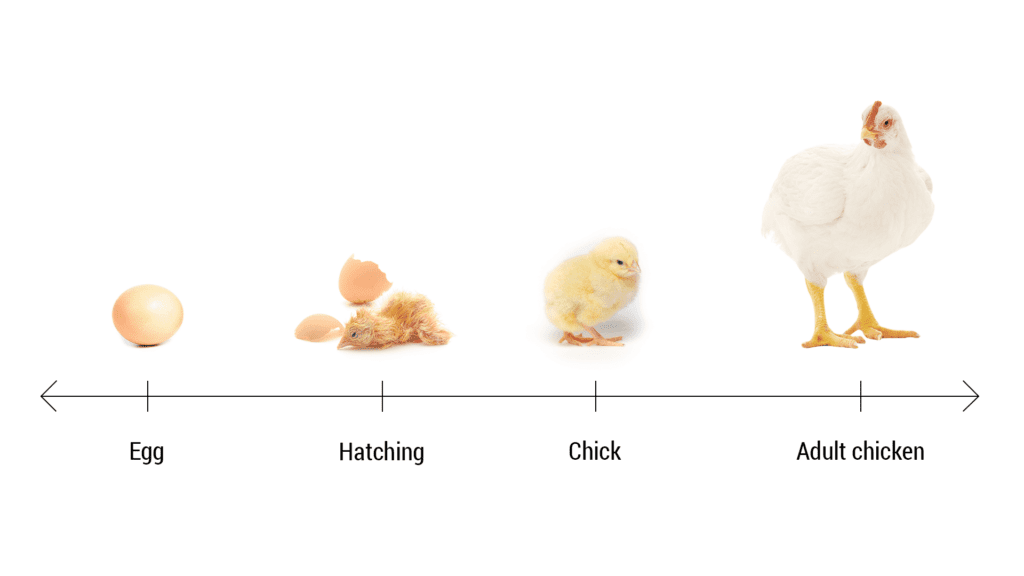

The maize kernel is composed of three basic morphological parts: pericarp, germ, and endosperm. The endosperm represents 75%–80% of the maize kernel, while the pericarp and germ account for 5%–6% and 10%–12% of the kernel weight, respectively. Starch, the primary carbohydrate in maize, comprises around 70% of the weight of the maize kernel on a dry matter (DM) basis. Maize starch contributes approximately 60% of the metabolisable energy (ME) content in broiler diets. The endosperm contains most of the starch and protein in the kernel. Most of the crude fat is contained in the germ, together with a relatively high level of protein and minerals. The carbohydrate, fat, and protein components all contribute to the overall energy value of maize and any variations in these nutritional components will alter the energy value in some way.

Kernel vitreousness

Vitreousness and kernel hardness play an important role in the processing of maize, and different industries and/or milling processes require different hardness levels. There are two types of endosperm. One is of higher density, harder, and more translucent, called the vitreous or horny endosperm, located on the outside of the kernel. The other is of lower density, softer, and mealy-textured, called the floury or opaque endosperm, located in the centre of the kernel. It has been shown that increased vitreousness in maize caused a linear decrease in the availability of starch and that endosperm protein composition and distribution determine the vitreousness.

Kernel hardness

Maize can be categorised into five classes according to kernel hardness. These classes range by decreasing vitreousness: flint, popcorn, flour, dent, and sweet. The predominant maize used in the South African dry maize milling industry is dent maize, which represents a hybridisation of flint and floury maize. Kernel hardness is mainly due to genetic expression, but transportation, drying, storage, and environment may also play a role in hardness properties. Hard kernels have a higher percentage of glossy endosperm, soft kernels have a higher percentage of floury endosperm, and intermediate kernels have an even distribution of glossy and floury endosperm.

The maize project

NIT spectroscopy as a method to determine energy and kernel hardness

Due to large variations in maize grain quality, the use of a rapid, automated system to determine grain nutrient content and quality is the most economical option to avoid inaccurate feed formulation. Near-infrared transmittance (NIT) spectroscopy is a non-destructive method used to determine energy and kernel hardness. This method requires no sample preparation, is quick and accurate, and can be used to analyse whole kernels, improving measurement repeatability and sample preservation. It is an ideal piece of equipment to have at the intake offices of silos for quality control purposes.

Model development and results

Maize samples collected by the Southern African Grain Laboratory from different regions in South Africa were analysed for various characteristics, including moisture, crude protein, crude fat, and milling index using NIT spectroscopy. The model predicted the energy values of several maize samples from proximate analysis as well as physical kernel characteristics, including milling index for kernel vitreousness and hardness. The final model was validated on an independent dataset of samples. The predicted and actual energy values of several maize samples was strongly correlated.

Improving maize energy estimation and prediction

Maize is a major component of broiler feed and consequently contributes largely to dietary energy values. It is therefore imperative to understand and quantify the nutritive value of maize to better estimate energy values. This will assist in improving feed formulation accuracy and thereby improve broiler performance, profitability, and sustainability. Therefore, in addition to proximate composition, physical characteristics of the kernel that contribute to observed variation in the energy of maize should be considered when predicting energy available to broilers.

Intern: Poultry

Well done, Sibong: very interesting and well written.