Progressive farming cannot exist without constant innovation and the search for improvement.

One of the greatest inventors of our generation, Steve Jobs, founder of Apple (the computers not the fruit), died earlier this year. What remains are his inventions and quotes on innovation.

Leading innovation, or the implementation of new ideas and gadgets, is rarely embraced by the masses from the outset.

It takes a few daring pioneers to try, test and implement innovation before it becomes part of everyday life. The trick is to implement innovation to generate more profit. As all farms are different, innovations deliver varying degrees of success, depending on an array of influencing factors.

Rations that add profit

Innovation at feed additive level, for instance, can be an expensive and futile exercise if good health, hygiene and handling management are not also on par.

A web-based calculator to determine the profit you can make by adding the right minerals to rations and taking care of hoof health, is part of a whole range of locally available innovative products. Assessing the economic value of Zinpro Performance Minerals in dairy rations, for example, is now made very easy and accurate with Zinpro Proof (product risk: opportunity or failure). This calculation system was developed in conjunction with Dr David Galligan, a dairy scientist from the University of Pennsylvania School of Veterinary Medicine.

“Innovation distinguishes between a leader and a follower.” – Steve Jobs

The programme uses information unique to each farm and herd, related to milk production, milk price, pregnancy value, cost per day open, product price (of supplements) and dry matter cost. The values are customised and can be altered by the farmer as they change in real terms.

The calculation results give an easily understandable visual display of the cost of failure (COF) and the increased revenue potential (IRP) difference.

COF occurs when an investment is made and the product does not perform at breakeven or better. IRP is the typical economic return to the producer when feeding the company’s minerals.

A decision meter on the results screen will indicate the actual rand value of using the company’s minerals, based on the difference between COF and increased revenue potential. Revenue implications will show the R/cow/year estimate of the increased revenue potential and cost of failure projections.

The likelihood of projected results will show the strength of decision estimate, showing how often producers can expect positive and negative economic results.

For example, when using one of the company’s products that combines zinc, manganese, copper and cobalt, the average benefits in your herd will be calculated based on 20 trials involving 4 301 cows.

Upgrade despite size

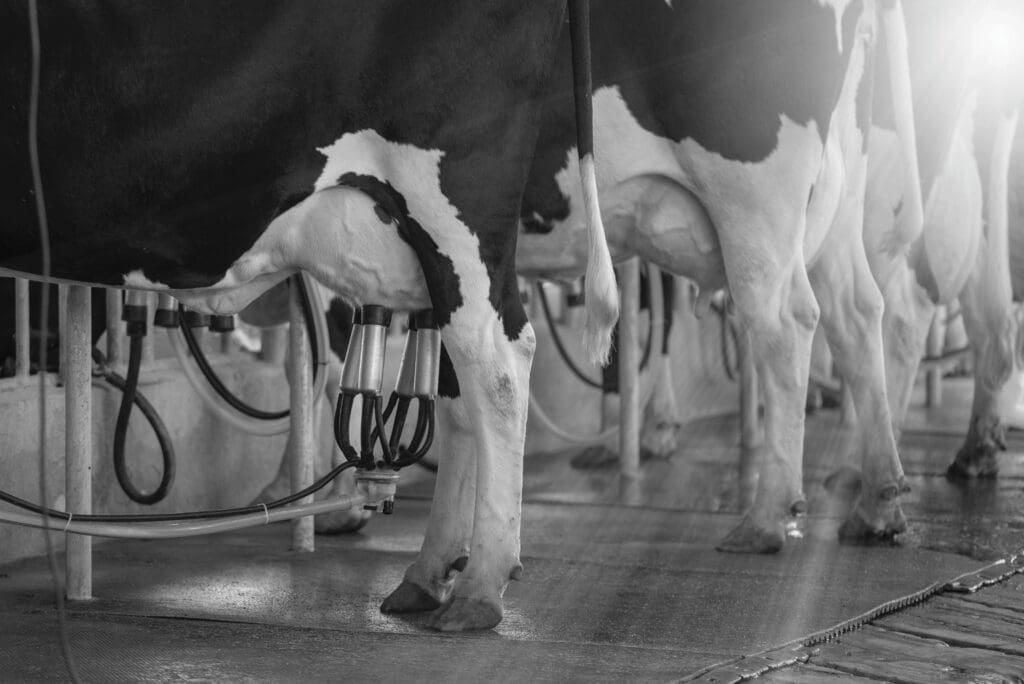

Many believe that technology is only for farms with large herds that ‘can afford’ it. However, Dirk and Suzette Venter farm near Brits with Holsteins and Jerseys in a combined milking herd of 140 cows. They started milking some 17 years ago with a 6-point milking system.

After upgrading to a 7-point and later an 11-point system, they decided to make a clean break and install a brand new milking system fitted with Waikato hardware and an Afikim electronic management system.

“This is an investment you can afford maybe once or twice in your career and for our farm and living circumstances, this upgrade has changed our lives,” says Suzette.

The couple has a few side-line businesses, including a garage, and their time is divided between various projects, management of their business and the dairy. The system helps the busy couple with all record keeping of treatments, artificial insemination and production levels.

The electronic monitoring of the animals with the help of a pedometer makes heat detection much easier and accurate. The computer software takes care of milk recording and detecting cows that are not performing according to their potential and stage of lactation, alerting the Venters to examine cows for possible treatment. Somatic cell count and the conductivity of the milk show the possible prevalence of mastitis, for instance, and these cows are immediately separated for specific attention.

“One cannot afford to stay behind when it comes to technology that can help you farm more efficiently,” says Dirk.

Besides the time and peace of mind the couple has gained regarding some management aspects of their herd, their improved understanding of the herd health and production has made culling decisions easier and treatment more efficient. The combined result is a much lower SCC and the added bonus of a 25c premium.

According to them, the system would have paid for itself within two years if one only calculates the benefits.

For large herds, the benefits are obviously more pronounced. By using the fully integrated management and feed system, where cows are fed individually, the results are astounding, says Murray Versfeld, managing director of Waikato South Africa.

The results of a 900 cow herd (feeding to weight) showed a saving of 40g per litre of milk produced.

Invest in innovation

Not all new technology entails computers and gadgets. From the innovation hub at GEA Farm Technologies comes SensoDip 50R, a teat dip that protects the teats from mastitis pathogens and includes a fly repellent. This also results in substantially reduced levels of insect irritation on the udder and diseases spread by flies.

ProfilacDryOff is an innovative latex-based teat dip for dry cows, which seals the teat opening and keeps all pathogens from entering the teat canal. The teat dip stays on the teat for several days if applied properly.

“Here’s to the crazy ones, the misfits, the rebels, the troublemakers, … the ones who see things differently — they push the human race forward, and while some may see them as the crazy ones, we see genius, because the ones who are crazy enough to think that they can change the world, are the ones who do.” – Steve Jobs

Moving up on the technology and price scale is the invention of a four-way milking cluster. This revolutionary four-way technology, dubbed IQ by GEA Farm Technologies, is the first such cluster of its kind.

The milk guide piece has been designed following the natural structure of a cow’s udder. It is sub-divided into four guide chambers. As opposed to conventional systems, the milk is lead by individual quarter and channelled to the outlet. Thanks to the incline in the respective cluster chamber, this process is now faster and much more gentle.

This prevents teat-to-teat cross-contamination and the automatic vacuum switching system only activates the full vacuum for each of the four quarters when the teat cup has been closed by the teat. The vacuum remains stable, which means that air slurps and the resulting contamination of the milk path are virtually eliminated.

Chemuniqué empowers feed and food producers with the most innovative animal performance solutions, enabling our clients to consistently advance the efficiency of production.